CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

Elastic coupling

TIME:2017-08-21 AUTHOR:admin

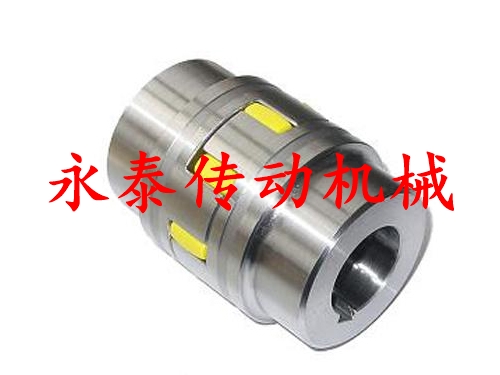

Name: elastic coupling

Description: elastic couplings are usually cut from metal round rods, commonly used in aluminum alloy, stainless steel and engineering plastics.

Tags: LMS (MLS) - double flange quincunx elastic coupling LMZ - Ⅱ type (the original MLL - Ⅱ) with brake wheel quincunx elastic coupling

Product details:

Elastic couplings are usually cut from metal round rods, commonly used in aluminum alloy, stainless steel and engineering plastics.

The flexible coupling USES parallel or spiral grooved systems to accommodate various deviations and precise transmission of torque. Elastic couplings usually have good performance and price advantages. In many steps and servo system applications, elastic couplings are preferred products. The integrated design makes the elastic coupler realize zero clearance of torque and the advantage of unnecessary maintenance. The elastic coupling mainly consists of two basic series: spiral groove type and groove type.

Characteristics of elastic coupling

(1) metal elastomer formed in one body;

(2) zero rotation clearance and synchronous operation;

(3) elastic compensation for radial, angular and axial deviation;

(4) high torque rigidity and excellent sensitivity;

(5) clockwise and anticlockwise rotation characteristics are identical;

(6) maintenance, oil and corrosion resistance;

(7) the selection of aluminum alloy and stainless steel materials;

(8) the fixed mode mainly has the top wire and clamping two kinds.

Elastic coupling application

Most of the elastic couplings are made of aluminum alloy, some of which also provide flexible coupling of stainless steel materials. In addition to corrosion resistance, stainless steel elastic couplings also increase torque endurance and rigidity, and can even reach twice as much as aluminum alloy products. However, this increased torque and rigidity will be partially offset by increased mass and inertia. Sometimes the negative impact will outweigh its benefits, so the user has to look for other forms of couplings.

Elastic coupling fixed mode

1. Elastic coupling positioning screw fixation: two positioning screw gaps: 90 & ordm; The locking of the fixed axis, the traditional fixed way, because the screw's front end and the axial contact, may cause the axis damage or disassembly difficulties.

2. The lins elastic coupling clamping screw fixation: use the inner hexagonal bolt to tighten the tight force, make the slit shrink, and hold the axis tightly. This method is easy to fix and disassemble, and it does not cause the shaft damage. It is a very common fixed way.

3. Flexible coupling key groove type fixed: suitable for high torque transmission, to prevent axial slide, usually fixed with positioning screw and clamping screw.

4. Elastic coupling D word hole is fixed: usually, if the motor shaft is a D type, if positioning screw cannot be fixed, can coupling hole processing into corresponding to the size of the motor shaft type D hole, fit positioning screws, do not have to worry about slip.

5. Heave tight set of fixed: through tight LingSi coupling end of the four positioning screw compression lhe swelling fixed account set way, suitable for the large torque of stepping motor and servo motor coupling fixed, such as assortments of diaphragm coupling, plum coupling, expansion bellows coupling, expanding set of elastic coupling, etc.