CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

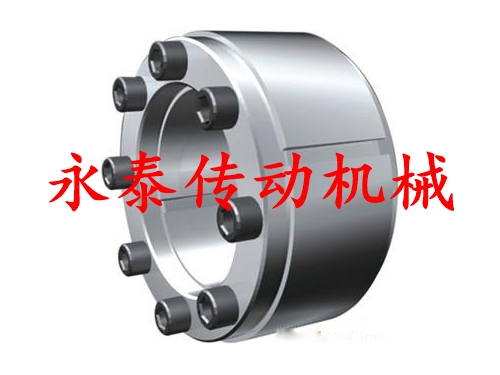

Expansion joint

TIME:2017-08-21 AUTHOR:admin

Name: bulking joint

Description: the main function of the bulging coupling is to replace the bonding of single and spline keys to realize the connection of the machine parts (such as gears, flywheel, pulley, etc.) and the shaft to transfer the load.

Label: JQ clamshell stainless steel coupling JQ type clamshell coupling packing box

Product details:

The main function of the bulging coupling is to replace the bonding of the single bond and the spline, to realize the connection of the machine parts (such as gears, flywheel, pulley, etc.) and the shaft to transfer the load.

The application of the bulging coupling sleeve

Lhe swelling link sets are widely used in the implementation part and shaft coupling, by tight 12.9 high strength screw tolerance between the pressure and friction to achieve load transfer of a new type of keyless coupling device. As a kind of advanced foundation, the industrial developed countries in the 1980s, such as Germany, Japan and the United States, have adopted this new technology widely in mechanical joints under heavy loads. In the wheel and shaft coupling, it is to rely on tight high strength bolt the tolerance between the pressure and friction load transmission of a keyless connection device, in order to realize the object (e.g., gears, flywheel and pulley, etc.) and the shaft coupling, to carry the load. It USES high strength bolt to make the inner ring and the shaft between the outer ring and the hub. When the load is under load, the combined pressure of the coupling and the combined force of the machine parts can be used to transfer the torque, axial force or the combined load of both.

Advantages of tightening coupling sleeve:

1. Make the machine parts manufacturing and installation simple by using the bulging coupling. The shaft and hole of the mounting and tightening coupling are not required to make high precision manufacturing tolerances. It is not necessary to heat, cool, or pressurize the attachment when it is installed, only to tighten the bolt to the required torque. With convenient adjustment, the hub can be easily adjusted to the desired position on the axis. The bulging coupling can also be used to connect the welded parts.

2. Long service life and high strength. The expansion tight coupling relies on friction transmission, no keyway for the connected parts, no relative motion, no wear and tear in the work.

3. When the tension connection is overloaded, the coupling function will be lost and the equipment can be protected from damage.

4. The expansion and tightening coupling can withstand multiple loads, and its structure can be made into many styles. According to the installation load, it can also be used in series.

5. It is convenient to disassemble the coupling sleeve and has good interchangeability. It is easy to disassemble the connecting piece by loosening the bolt when it is disassembled because it is able to combine the shaft hub of the larger fit clearance. When the tension is tight, the contact surface is not easily corroded and easy to connect and disassemble.