CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

JSB axial mounting coupling

TIME:2018-03-13 AUTHOR:admin

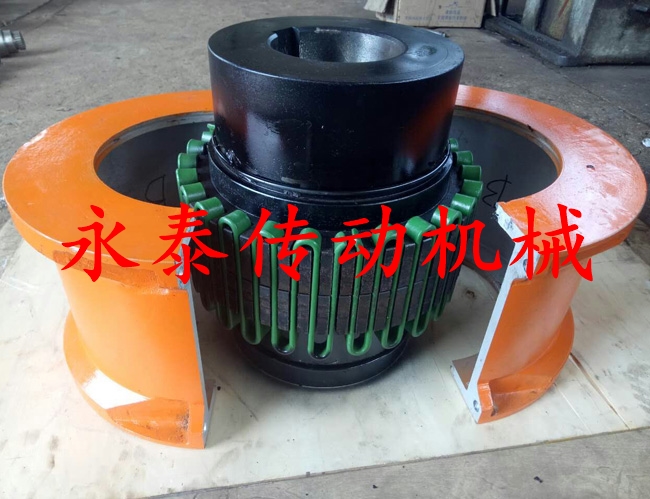

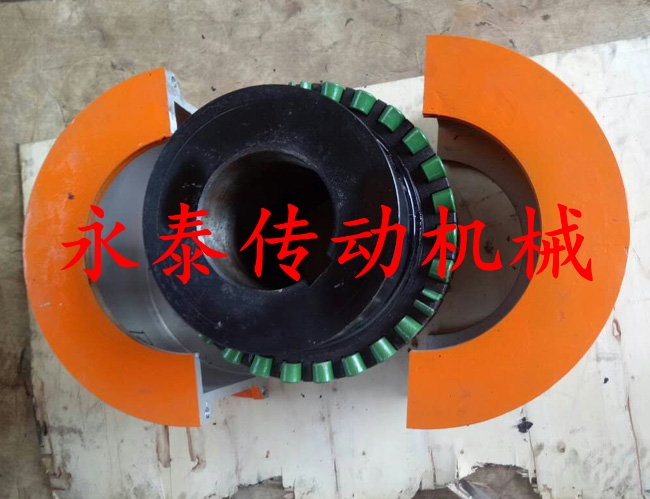

Name: JSB type axial mounting coupling

Description: JSB coupling of axial installed in various host products, surrounding environment is more complex, such as temperature, humidity, water, steam, dust, sand, oil, acid, alkali, corrosion medium, the condition of salt water, radiation and so on, is to choose one of the important factors that must be considered when the coupling.

Label: JSJ type coupling type coupling type coupling JSS type coupling JSS double flange coupling type coupling

Product details:

JSB coupling of axial installed in various host products, surrounding environment is more complex, such as temperature, humidity, water, steam, dust, sand, oil, acid, alkali, corrosion medium, the condition of salt water, radiation and so on, is to choose one of the important factors that must be considered when the coupling. For high temperature, low temperature, oil, acid, alkali medium quality of work, unfavorable choose by the general rubber for the elastic element material of flexible coupling, flexible coupling should choose metal elastic component, such as the diaphragm coupling, snake-like spring coupling, etc.

The JSB axial mounting coupling is a kind of advanced metal elastic coupling. Axial embed it in serpentine spring leaf half coupling tooth groove, to realize the connection of the prime mover and work machine, due to the special properties of the reed, which largely avoided the prime mover and work machine resonance phenomenon, service life is much higher than non-metallic elastic element coupling; Reed contact tooth surface is curved, the size of contact area changes with the size of the transmission torque, so it can bear larger load changes, the determination of its short-term overload capacity of 2 ~ 3 times of the rated torque, the transmission efficiency of 99. 5%, safe and reliable operation.

| NO. | Nominal torque Tn KN.m | Max speed (n) r/min | R | L | L0 | L2 | L3 | D | t | Mass kg | Lubricating oil kg | Max D | ||

| y | x | a | ||||||||||||

| JSB1 | 0.045 | 6000 | 18-28 | 47 | 97 | 48 | 24 | 112 | 3 | 2 | 0.027 | 0.15 | ±0.3 | 0.076 |

| JSB2 | 0.14 | 6000 | 22-35 | 47 | 97 | 48 | 25 | 122 | 3 | 2.6 | 0.048 | 0.15 | ±0.3 | 0.076 |

| JSB3 | 0.224 | 6000 | 25-42 | 50 | 103 | 51 | 26 | 130 | 3 | 3.4 | 0.054 | 0.15 | ±0.3 | 0.076 |

| JSB4 | 0.4 | 6000 | 32-50 | 60 | 123 | 61 | 31 | 149 | 3 | 5.5 | 0.068 | 0.20 | ±0.3 | 0.10 |

| JSB5 | 0.63 | 6000 | 40-56 | 63 | 129 | 64 | 32 | 163 | 3 | 7.3 | 0.086 | 0.20 | ±0.3 | 0.127 |

| JSB6 | 0.90 | 5500 | 48-65 | 76 | 155 | 67 | 34 | 174 | 3 | 10 | 0.113 | 0.20 | ±0.3 | 0.127 |

| JSB7 | 1.80 | 4750 | 55-80 | 89 | 181 | 89 | 44 | 200 | 3 | 18 | 0.172 | 0.20 | ±0.3 | 0.15 |

| JSB8 | 3.15 | 4000 | 65-95 | 98 | 199 | 96 | 47 | 233 | 3 | 26 | 0.254 | 0.20 | ±0.3 | 0.18 |

| JSB9 | 5.6 | 3250 | 75-110 | 120 | 245 | 121 | 60 | 268 | 6 | 42 | 0.427 | 0.25 | ±0.5 | 0.20 |

| JSB10 | 8.0 | 3000 | 80-120 | 127 | 259 | 124 | 63 | 287 | 6 | 55 | 0.508 | 0.25 | ±0.5 | 0.23 |

| JSB11 | 12.5 | 2700 | 90-140 | 149 | 304 | 143 | 74 | 320 | 6 | 82 | 0.735 | 0.28 | ±0.5 | 0.25 |

| JSB12 | 18 | 2400 | 110-170 | 162 | 330 | 146 | 75 | 379 | 6 | 123 | 0.908 | 0.28 | ±0.5 | 0.30 |

| JSB13 | 25 | 2200 | 120-200 | 184 | 374 | 156 | 78 | 411 | 6 | 180 | 1.135 | 0.28 | ±0.5 | 0.33 |

| JSB14 | 35.5 | 2000 | 140-200 | 183 | 372 | 204 | 107 | 476 | 6 | 230 | 1.952 | 0.30 | ±0.5 | 0.40 |

| JSB15 | 50 | 1750 | 160-240 | 216 | 438 | 216 | 115 | 533 | 6 | 322 | 2.815 | 0.30 | ±0.5 | 0.45 |

| JSB16 | 63 | 1600 | 180-260 | 216 | 438 | 226 | 120 | 584 | 6 | 449 | 3.496 | 0.30 | ±0.5 | 0.50 |