CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

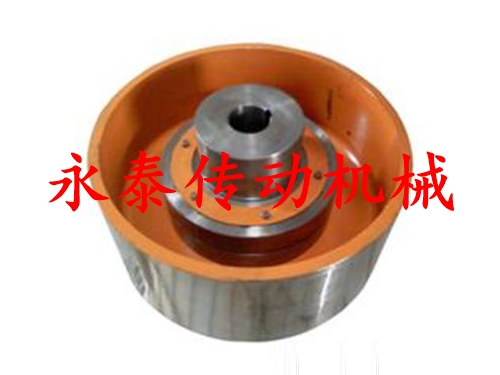

ZLL wheel shaft coupling

TIME:2017-08-21 AUTHOR:admin

Name: ZLL type belt brake wheel shaft pin coupling

Description: the applicability of the ZLL type brake roller pin coupler is applicable to the transmission shafting of the two coaxial lines, with a certain compensation of two axis relative deviation and general damping performance.

Label: Z2 expansion tight sleeve Z3 tightening sleeve Z3

Product details:

The applicability of the ZLL type brake roller pin coupler is applicable to the transmission shafting of the two coaxial lines, with some compensation for the relative deviation of the two axes and the general damping performance.

Working environment temperature is 20 ~ + 70 ℃. Do not apply to the high requirement of the damping effect and on the part of the need to control noise.

The basic parameters and main dimensions of the couplings of the ZLL type brake roller pin couplings are:

Nominal torque Tn: 250N. M

Allowable speed n: 4000r/min

Shaft diameter d: 16, 18, 19, 20, 22, 24, 25, 28, 30, 32mm

Axis length Y: 42, 52, 62, 82, J1 type: 30, 38, 44, 60mm

Brake wheel D0:160mm

Outer diameter D: 102mm

ZLL type belt wheel elastic dowel pin shaft coupling is the use of a number of non-metallic materials of the dowel pin, placed in two and a half coupling between inner surface and outer ring the involution of the hole, achieved by column pin transfer torque half coupling, the coupling has the following features:

(1) the transmission torque is large, and in the same torque, most of the rotating diameters are smaller than the tooth coupling, small in size and light in quality, which can be partially replaced by the dental coupling.

(2) compared with the gear type coupling, the elastic cylindrical pin gear coupling is simple in structure, with less components and more convenient manufacturing, and no gear processing machine.

(3) the flexible cylindrical pin gear shaft is easy to maintain and has a long life, so it can replace the nylon pin.

(4) the nylon pin of the elastic cylindrical pin gear spindle is self-run material, which does not need to be lubricated and not only saves the lubricating oil, but also purifies the working environment.

(5) the vibration can be poor and the noise is larger.