CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

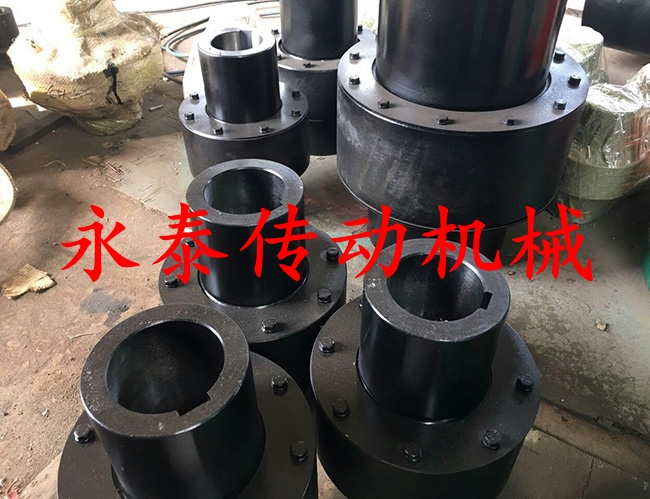

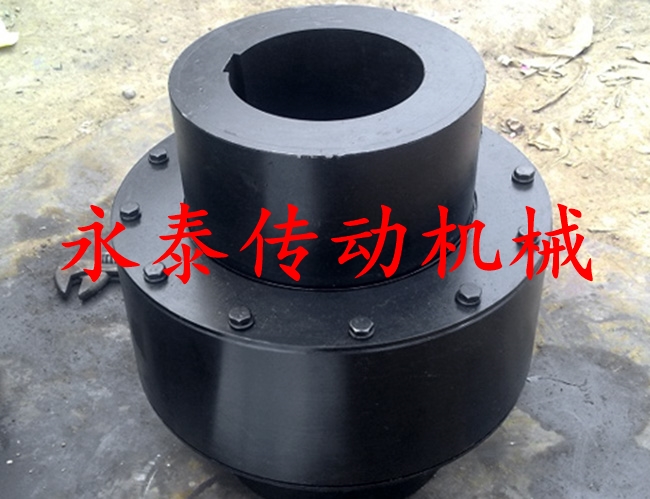

Elastic pin coupling

TIME:2018-03-13 AUTHOR:admin

Product introduction:

Elastic cylinder pin couplings are generally used for elastic column pin couplings and nylon rod pin couplings. The former is a few screw connections, and the screw nut end is fitted with elastic gasket. The latter is to use nylon rods, form a complete set of two and a half day as big drill holes, nylon rods in them, with baffle a cover outside, dowel pin shaft coupling, dowel pin coupling put that more simply is to connect the two and a half shaft section presents N nylon rods connected. It can compensate.

Commonly used model: elastic sleeve pin coupling (TL), elastic pin coupling (HL), elastic cylindrical pin coupling (LZ).

ZL type coupling type elastic dowel pin and main dimensions using several basic parameters of non-metallic materials of the dowel pin, placed in two and a half coupling between inner surface and outer ring the involution of the hole, achieved by column pin transfer torque half coupling.

LT (TL) column elastic sleeve pin coupling (instead of GB4323 GB4323-2002-2002) column elastic sleeve pin coupling is the use of one set of elastic sleeve pin (rubber) column, in a two and a half coupling flange hole, so as to realize the connection of two half-coupling. Column elastic sleeve pin coupling was once a coupling device of the most widely used in our country, as early as the late 1950 s, which is for the mechanical standards, JB08-60 elastic dowel pin coupling, is China's first standard coupling.

HL type - resilient column pin coupling has been listed as the national standard gb5014-85, which is suitable for the transmission shaft of two coaxial lines of mechanical connection, usually used for high and low speed movement. Working temperature is 20 ~ + 80 ℃; The transfer torque is 40 ~ 20000n. m. The flexible cylindrical pin coupler has the advantages of simple and reasonable structure, convenient maintenance and double symmetry, and long life, which allows for large axial movement, cushioning, damping, abrasion resistance and so on.