CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

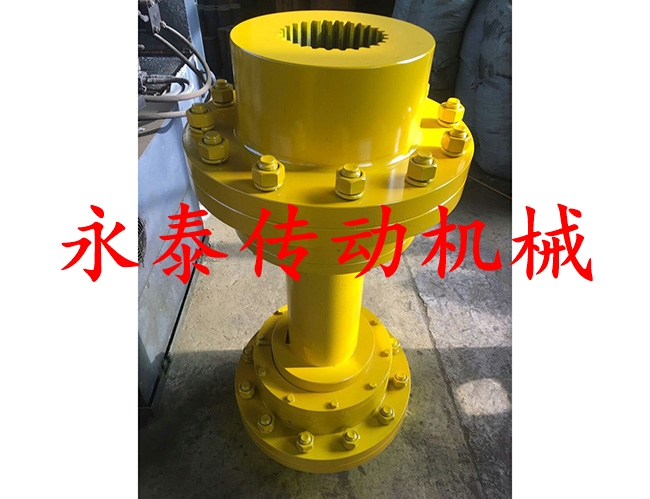

Drum gear coupling

TIME:2017-08-22 AUTHOR:admin

The characteristics of drum gear coupling (compared with the straight teeth coupling)

1. Strong carrying capacity. The load capacity of drum tooth coupling is 15 ~ 20% higher than that of the straight gear coupling in the same inner tooth casing and the maximum outer diameter of the coupling.

2. The offset of angular displacement is large. When the radial displacement is equal to zero, the allowable angular displacement of the direct tooth coupling is 1 & ordm; The allowable angular displacement of drum gear coupling is 1 & ordm; 30 ', up to 50%, with the same modulus, teeth, and width of the teeth, the drum teeth are larger than the allowed angular displacement of the straight teeth;

3, drum gear tooth surface of internal and external tooth contact conditions improved, avoided under the condition of angular displacement straight tooth gear tooth edge extrusion, the disadvantages of stress concentration, and at the same time improve the tooth surface friction, wear, reduced the noise, maintenance cycle is long;

4. The outer teeth of the outer teeth are honked in shape, making it convenient for the inside and outer teeth to be removed.

5. The transmission efficiency is up to 99.7%. Based on the characteristics, it is widely used in the world to replace the straight tooth coupling with drum teeth. The drum gear type couplings in UMA are complete specifications and meet the corresponding standards. Drum gear type coupling, rigid, flexible and inelastic, so it is not suitable for the requirement of vibration reduction, buffer and two shafts to require strict machinery.

The drum type coupling can compensate the adaptive and self-tuning technology of the load change, especially the high-end drum gear coupling with the distributed communication and networking functions and integrated PLC. On the other hand are simple or industry-specific drum gear couplings and electromechanical integration and miniaturized drum gear couplings. Drum gear coupling is a key equipment to save energy. According to the network media statistics, at present domestic belt fluctuating load, the motor with energy saving potential has at least 180 million kilowatts, thus providing a huge market for the application of drum gear coupling. Drum type coupling has been applied by common fan, water pump, etc to food, beverage, logistics, building, etc., and constantly open new energy field, its function also improved and diversification, on the one hand, is a fully digital, the function is all ready, in addition, due to the advent of new high voltage power electronic device, high voltage and medium voltage drum type coupling also has a great development.