CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

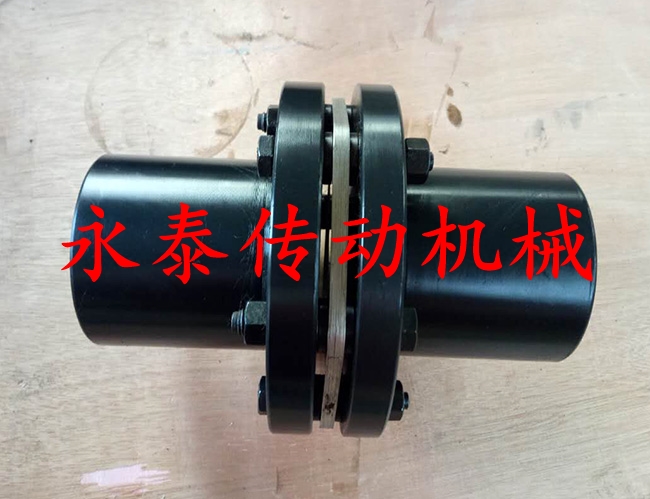

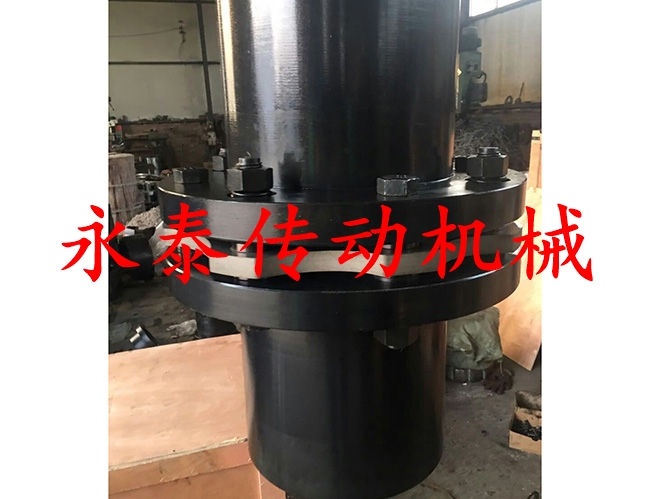

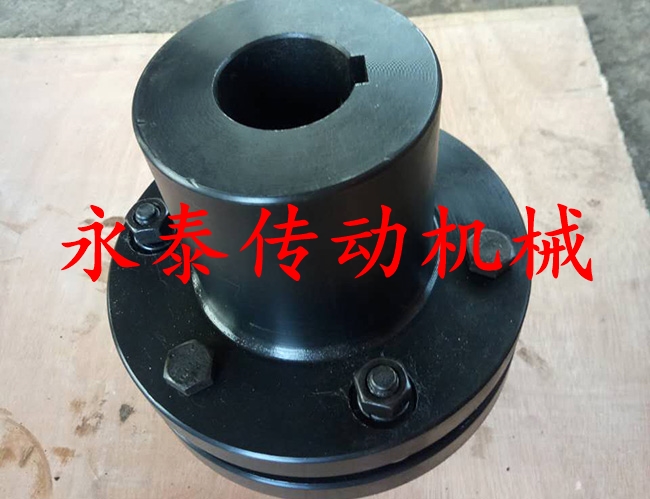

Single diaphragm coupling

TIME:2017-08-22 AUTHOR:admin

Details:

The single diaphragm coupling consists of a diaphragm and two sleeves. Diaphragm is used pin fastening on the axle housing generally not loose or cause between the diaphragm and the shaft sleeve recoil, single diaphragm coupling was not comfortable with eccentric and double diaphragm coupling can tune in different directions at the same time, in order to compensate the eccentric. Select our products according to your needs, or call our customer service phone for consultation.

Features:

The features are a bit like bellows couplings, and in fact the couplings deliver torque in almost the same way. The diaphragm itself is very thin, so when the relative displacement load is generated it is easy to bend, so it can withstand a deviation of up to 1.5 degrees, while producing a lower bearing load in the servo system. The diaphragm coupling is often used in servo system, the diaphragm has good torque rigidity, but it is less than the bellows coupling. On the other hand, the diaphragm coupling is very delicate and can be easily damaged if used incorrectly or not properly installed. So it is necessary to ensure that the deviation is within the normal operation of the couplings. Selecting a suitable coupling is a key step in using a good coupling, and the type of coupling should be considered during the design phase.

Advantages:

Compared with the gear coupling, the diaphragm coupling has no relative slip, no lubrication, no sealing, no noise, no maintenance, convenient manufacturing, and a partial replacement of the dental coupling. Diaphragm coupling application is very common in industrialized countries in the world, has been to develop machinery industry standard in our country, has recently been revised for the new industry standard: JB/T 9147-1999 (instead of ZB J19022-90 / T) coupling relationship between the torque.