CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

DJM diaphragm coupling

TIME:2017-08-22 AUTHOR:admin

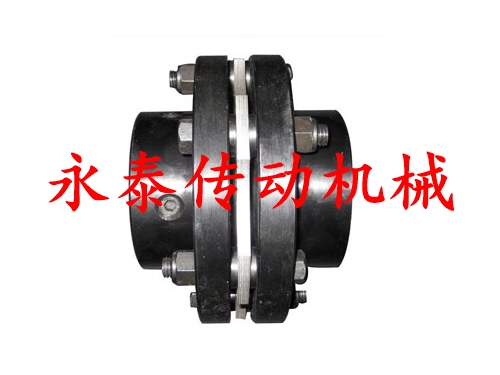

Name: DJM type diaphragm coupling

Description: the DJM diaphragm coupling is the integral type of diaphragm coupling. The DJM type diaphragm coupling has an eccentric allowable range and fast disassembly. No noise, wear, no sliding, friction rotating parts, can reduce energy loss; Light weight, suitable for high speed operation; High transmission accuracy and long service life.

Tags: JZM type heavy machinery with the diaphragm coupling diaphragm type coupling JM Ⅱ sink hole basic diaphragm coupling

Product details:

The DJM diaphragm coupling is the integral type of diaphragm coupling. The DJM diaphragm coupling has a wide range of eccentricity and fast disassembly. No noise, wear, no sliding, friction rotating parts, can reduce energy loss; Light weight, suitable for high speed operation; High transmission accuracy and long service life.

DJM type diaphragm coupling consists of several groups of diaphragm bolts crisscross and two and a half coupling, each group composed of several pieces fold sets of diaphragm, diaphragm, made of stainless steel sheet, can be divided into the connecting rod type and different shapes of the chip.

The DJM diaphragm coupling has the advantages of vibration absorption, no wear and no maintenance. It is the ideal product for replacing the tooth type coupling and general couplings, and the standard of the implementation of the plant is (JB/t9147-1999).

Main features of DJM diaphragm coupling:

1. Simple structure and light weight.

2. High transmission accuracy, high reliability, strong stability and long life.

3. The eccentricity allows wide range and can be used flexibly in various transmission systems.

4. Easy to remove and assemble, with high assembly importance.

5. Good environmental adaptability, acid and alkali resistance, corrosion resistance, high temperature operation.

6. No maintenance is required, and the naked eye can check for failure during downtime.

7. No lubrication, no noise, wear. No sliding, friction, rotating parts can reduce energy loss.

The DJM type diaphragm coupling is driven by two flanges coupling and a set of diaphragm. The following requirements should be noted during installation:

1. Remove dust and dirt from the surface of the shaft and wipe it clean.

2. Clean the inner hole of the diaphragm coupling, oil or lubricant;

3. Insert the diaphragm coupling into the mounting shaft, such as the tight aperture, and avoid hitting the installation with a hammer or hard metal;

4. After the positioning is completed, first press the diagonal direction, and tighten the screw gently with torque wrench (1 quarter of the specified tightening torque);

5. Step up force (1/2 of the tightening torque) to complete the fourth step;

6. Tighten the torque to tighten the fixed torque according to the specified tightening torque;

7. Finally, tighten the fixed screw in the circular direction;

8. When disassembling, please proceed at the complete stop of the device.