CATEGORIES

Stand of reducer

Agitator

Diaphragm coupling

Grid coupling

Roller chain coupling

Star type elastic coupling

Drum gear coupling

Elastic pin coupling

Bushed pin type coupling

Quincunx elastic coupling

Elastic pin gear coupling

Rotary shaft coupling

Safety coupling

Case coupling

Flange coupling

Water pump coupling

Industrial expansion sleeve

Coupling with rubber type elem

Cross slide coupling

Nylon tooth coupling

Coupling parts

Stuffing box

Brake

Reducer

Mr.Guo:+86-13127302466

Mr.Wang:+86-15100731866

Q Q:2814565957(Mr.Guo)

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

Q Q:2690587660(Mr.Wang)

Telephone:+86-0317-7513408

Address:Xiaoduzhuang village, Botou town, Cangzhou city, Hebei province

NEWS

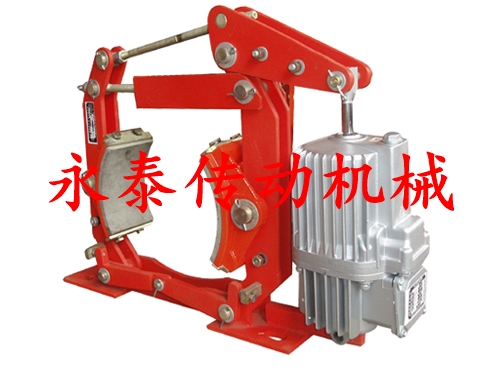

YWZ9 Brake

TIME:2017-08-21 AUTHOR:admin

Name: YWZ9 series electric hydraulic block brake

Description: YWZ9 series electric hydraulic block brake is the brake. A mechanical part that stops or slows the motion of a machine. Commonly known as brake and brake. Brake mainly consists of frame, brake and control device.

Label: ZWZ2 series dc electromagnetic block brake DCPZ12.7 series electromagnetic clamp disc brake

Product details:

YWZ9 series power hydraulic block brake is the brake. A mechanical part that stops or slows the motion of a machine. Commonly known as brake and brake. Brake mainly consists of frame, brake and control device. Some brakes are also equipped with automatic adjustment devices in the gap of brake parts. In order to reduce braking torque and structure ", brake is usually installed on the equipment of high-speed shaft, but for the high security requirements of the large equipment, such as the mine hoist, elevators, etc.) should be installed near the equipment work on the part of the low speed shaft. Some brakes have been standardized and serialized, and are manufactured by professional factories for use.

The structural features of YWZ9 series power hydraulic block brake are:

1. The axial size of the brake shaft is small, but the brake torque is large enough.

2. The quick loss of the electric brake is to use the spring device to form brake torque, and the spring reset time is the braking response time.

3. A new friction material can be used to determine the performance of high life.

The working principle of YWZ9 series electric hydraulic block brakes:

The brake is composed of magnetic yoke, excitation coil, spring, brake disc, armature, spline, mounting screws, etc. The brake is mounted on the back end of the device's flange (or motor). The transmission shaft is connected with the spline and the brake disc.

Brake on the excitation coil rated voltage (DC), the electromagnetic force and armature, armature and the brake disc from (release), then the shaft with the normal operation of brake disc or start, when the power transmission system separation or brake power at the same time, the spring pressure on the armature, forcing the brake disc and armature and the friction torque between the flange plate, rapidly halt the drive shaft. In the brake thermal environment is bad, drive shaft and continuous work for a long time, if the condition allows, can after brake job, keep voltage conversion is 70% - 80% of the rated voltage, to reduce the fever.